产品分类

产品分类

Function description

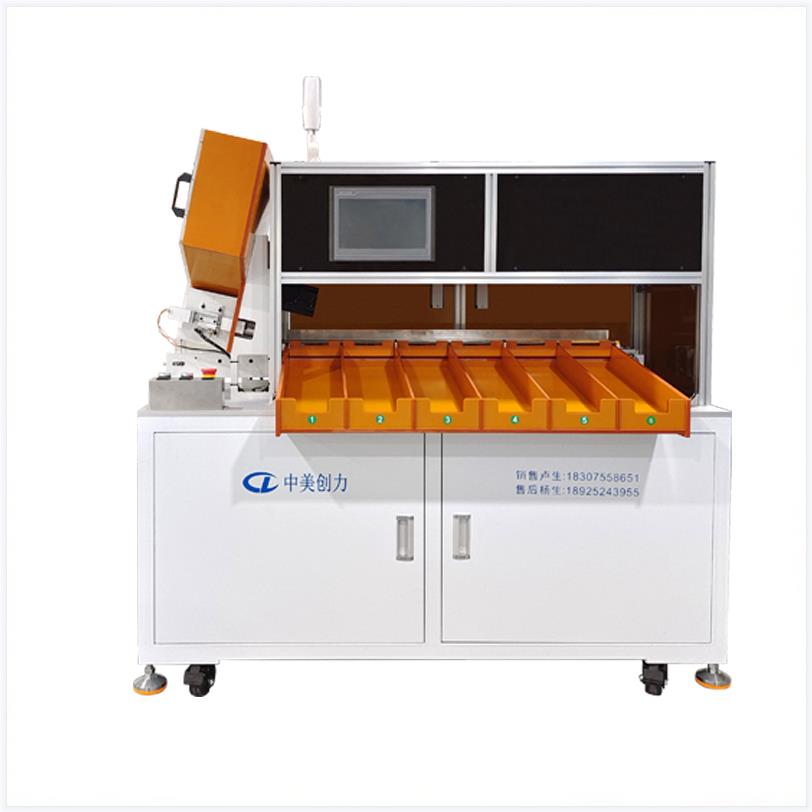

The 6-gear universal battery sorter is a testing and sorting equipment for the internal resistance, voltage and other parameters of cylindrical batteries. It is equipped with a high-precision internal resistance, voltage automatic testing system. The equipment accurately sends the batteries to the designated gear according to the internal resistance and voltage values set on the human-computer interface software. The system can achieve up to 6 gear sorting (5 OK gears, 1 NG gear). This equipment can test about 4200 electric cores per hour.

Features

1. Applicable cell: 32140/33138

2. The equipment is easy to operate, and workers can easily master it without professional training

3. The equipment is controlled by PLC+touch screen. PLC is responsible for battery feeding, material transportation, material receiving and other actions. The touch screen is responsible for battery test instrument data acquisition and storage, voltage internal resistance grade sorting and setting, battery parameter management, etc. The operation is simple and easy to learn, the work efficiency is high, the labor cost is saved, and the product performance is good.

4. The detection mechanism uses a special probe to measure two channels at the same time and adds a U-shaped magnetic positioning slot, which greatly improves the accuracy of the test without dividing the positive and negative poles.

5. Discharge structure

The chute structure design is simple and generous, which makes the discharging more rapid and orderly, and the system performance is stable. Five sorting and blocking channels and one unqualified channel are convenient for maintenance.

technological process

The internal resistance, voltage and other parameters of the battery are set through the software of the human-computer interface, and the following functions are automatically completed by the PLC: manually loading the battery → feeding by the feeding wheel → testing and sorting by the testing cylinder (data uploaded by the tester, software sorting) → battery transmission by the belt → cell sorting by the pushing cylinder to the specified gear; The equipment is equipped with audible and visual alarm, which can complete automatic shutdown, full material alarm, fault alarm, etc. The operating parameters can be set according to the actual requirements of customers.

Technical parameters of equipment

Working voltage: single-phase AC220V ± 5%/50Hz, power: P ≤ 700W

Working air source: 0.4~0.6Mpa

Applicable battery specification: 32140/33138 cylindrical cell

Separation efficiency: ≥ 70PPM

Equipment weight: about 200kg

Overall dimension: 1350 (long) × 820 wide × 1420 (H) mm

Sorter frame material: made of high-quality thick cold-rolled sheet.

Electric control devices: HMI, PLC, stepping motor control, brand sensors and other accessories are used.

Operation configuration: HMI

Instrument: Hopu HK3561

Sorting parameters: open circuit voltage, AC internal resistance

Open circuit voltage: accuracy+/- 0.10% rdg, display resolution 0.1 mV

AC internal resistance: accuracy+/- 0.5% rdg, display resolution 0.01 milliohm