产品分类

产品分类

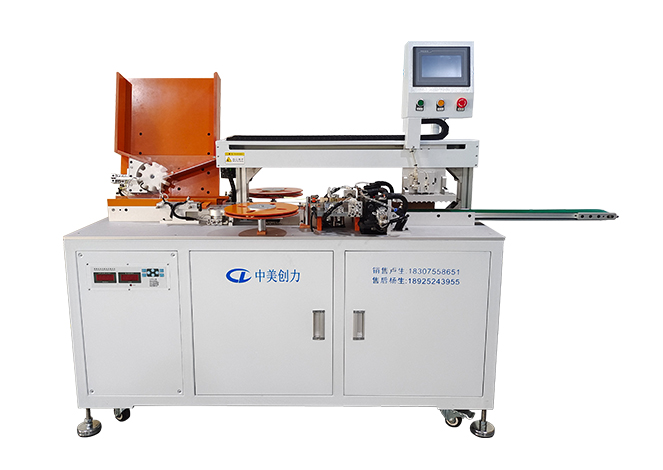

Equipment introduction

Cac-ydh-ps series parallel spot welding machine is a kind of equipment that splices cylindrical batteries in series parallel through nickel strips. The equipment can set the corresponding number of series parallel on the human-computer interface according to the product type. The system can realize series parallel welding in 10 cells at most and eliminate the manually discharged cells. At the same time, it is equipped with internal resistance test function, which can judge the internal resistance voltage. According to the splicing mode, this equipment can weld about 3000 electric cells per hour, with simple and generous structural design and stable performance. The system supports manual and automatic working modes with simple programming. The welding head is air-cooled to effectively reduce the heat loss of the welding needle.

technical parameter

Working voltage: single phase AC220 V ± 5% / 50 Hz, power: P ≤ 3500W

Use air pressure; 0.4-0.8Mpa

Scope of application: 18650 cells within 10 arbitrary series parallel combination

Suitable for nickel sheet: disc type nickel strip, width 5-8mm, customizable, thickness 0.1-0.15mm

Spot welding efficiency: About 1500-2500 cells / hour according to different splicing modes

Standard power supply: precision double pulse power supply, DC energy storage power supply optional

Electronic control devices: HMI, PLC, closed-loop motor control, brand sensors and other accessories.

Solder joint mode: single point / double point / three points optional, solder joint spacing adjustable

Equipment weight: About 200kg

Overall dimension: 1460 (length) × 670 (width) × 1450 (H) mm

Equipment display