产品分类

产品分类

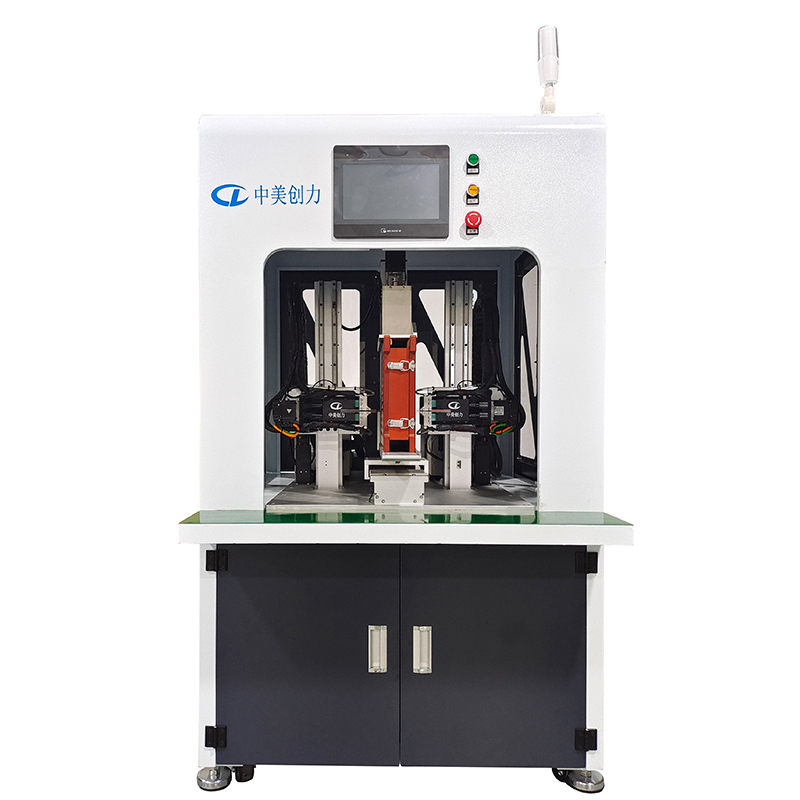

Equipment introduction

This equipment is mainly used for manual welding of battery and nickel plated steel strip or nickel strip in cylindrical / polymer battery combination, and ensure the welding tension of battery and nickel plated steel strip or nickel strip ≥ 30n. It is mainly used for spot welding of moulded lithium battery pack such as electric motorcycle / electric vehicle / solar street lamp.

Performance characteristics

1. Welding voltage locking technology can prevent the fluctuation of network voltage from affecting the welding current.

2. The welding pulse width is adjustable, the welding spatter is small, and the welding spot does not change color.

3. It has the function of two-stage current detection and comparison, and the sound and light alarm for abnormal current can effectively prevent the occurrence of false welding.

4. With fault self diagnosis function, display the corresponding fault point, convenient maintenance.

5. Using the embedded programming module of motion control card, just need to calibrate a starting point coordinate, input the number of X and Y axes, space, can automatically generate the welding head motion trajectory and save it in the system file, programming is simple and easy to learn.

6. 99 groups of welding procedures and parameters can be stored in the system, and the product can be replaced only by adjusting the energy and calling out the program. The welding head can be pneumatic, electric and rotary.

Product parameters

Input voltage / power: 380V / 220V optional, 3000W / 5000W

Overall dimension L * w * H: 1280 * 900 * 1650mm

Equipment weight: 350kg

Suitable for battery: 18650 / 26650 / 32650

Spot welding mode: single spot / double spot / three spot optional, support asymmetric spot welding

Cooling mode: circulating water cooling

Suitable thickness of nickel sheet: 0.1-0.3mm, grooving or bumping is required for more than 0.2

Welding head inlet spring pressure range: 1.0-5.0kg

72-75mm, 100mm wide

Average welding speed: 0.4-0.8s

Y-axis and z-axis stroke: 450mm * 450mm

Programming time: 1-3 minutes

Artificial aging: 2-3 people can be saved

Transmission mode: servo + imported precision screw + guide rail

Operating system: embedded motion controller + touch screen

Displacement accuracy: 0.05mm

Parameter storage: 99 groups

Welding power supply: Precision DC 5000A (standard configuration)

Welding current range: 800a-5000a adjustable, accuracy 1a

Equipment display